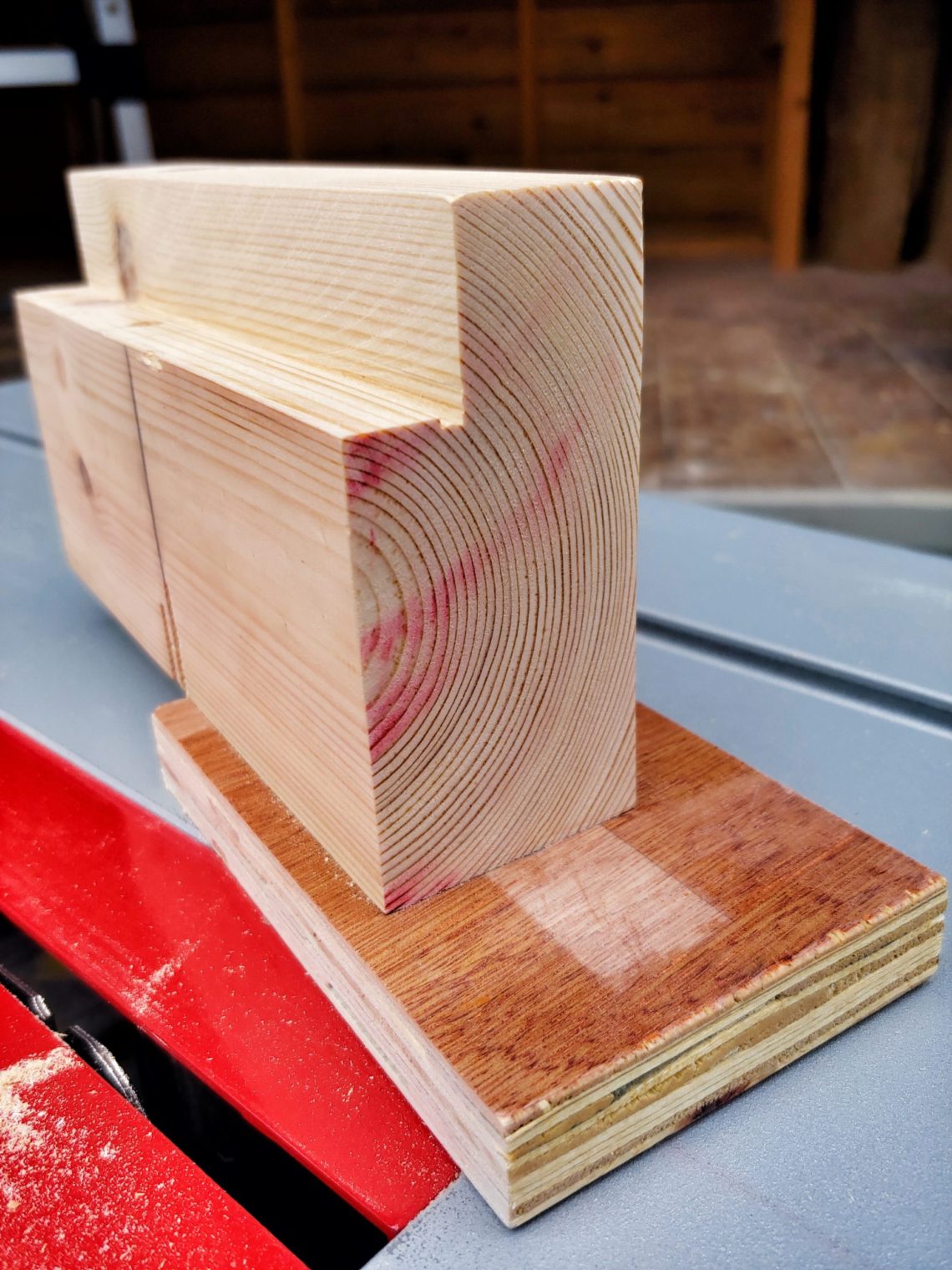

Finger joint jig

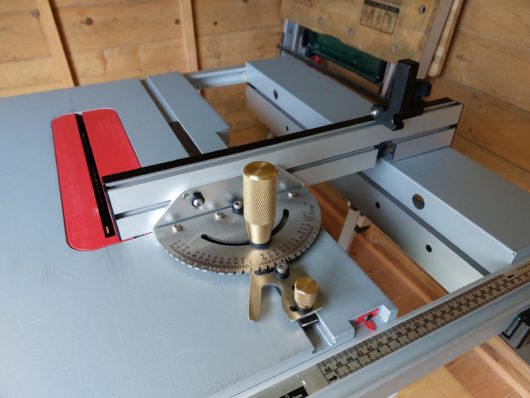

This is just an attachment for my table saw sledge, it can’t be used on its own. It’s made of scrap, unused and upcycled materials. Very cheap to make and didn’t take much time. It was one of these jigs that had to be made sooner or later as it is quite essential addition to any shop. There will be a new way to join wood, strong joints that also look good.

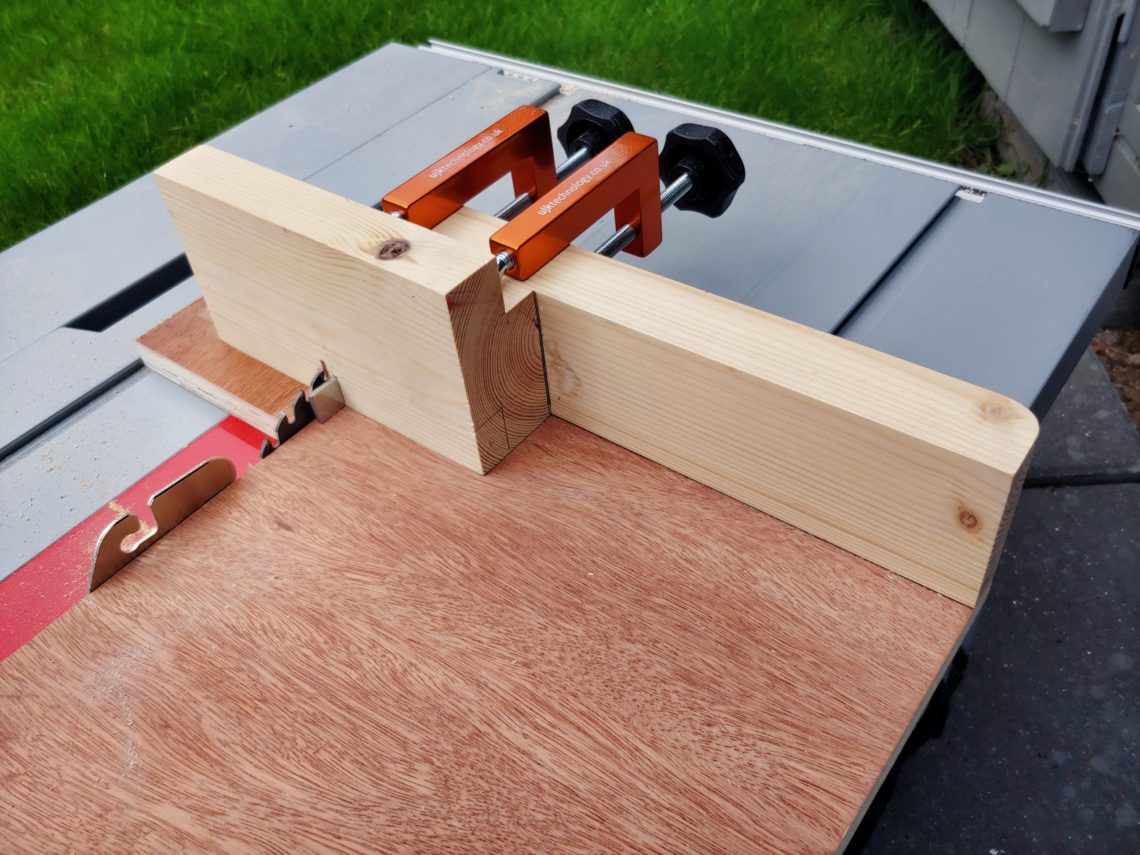

First I removed one corner from the timber block, and that was only done to get the same height as the backing fence it was going to be attached to. The clamps wouldn’t work properly with blocks of different heights.

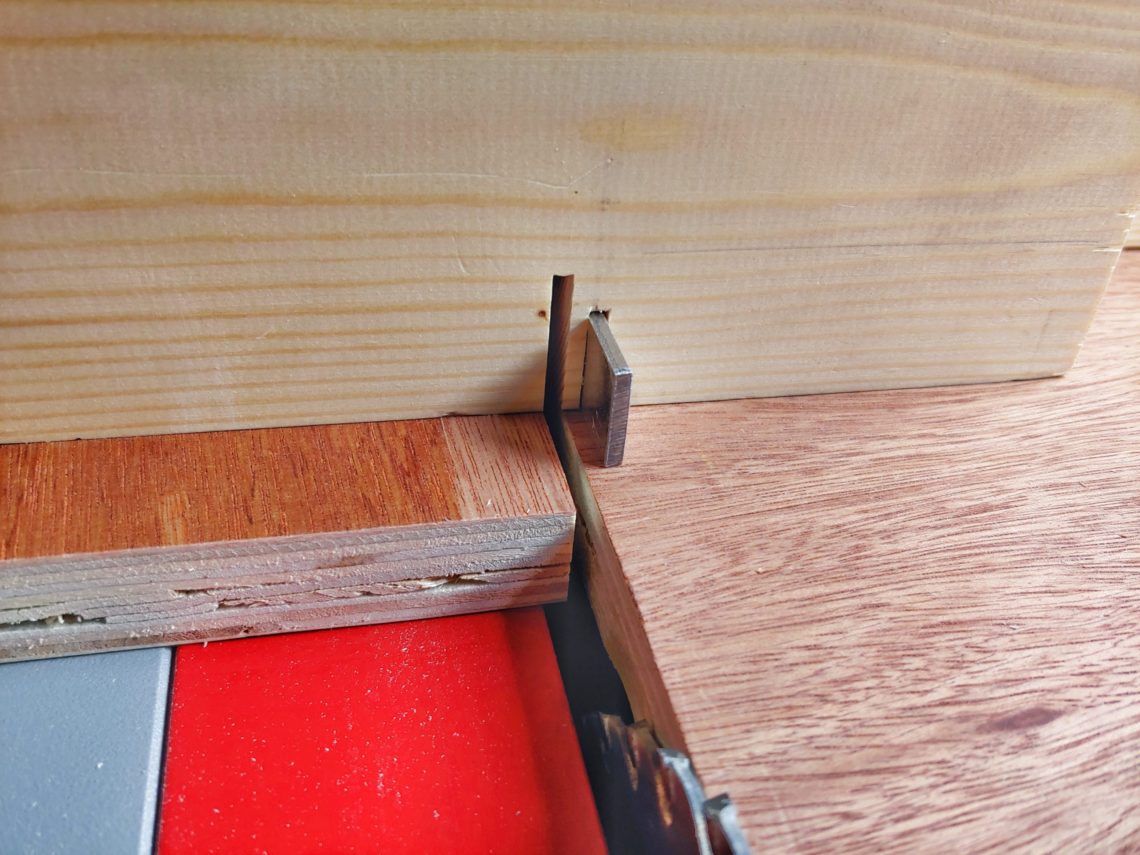

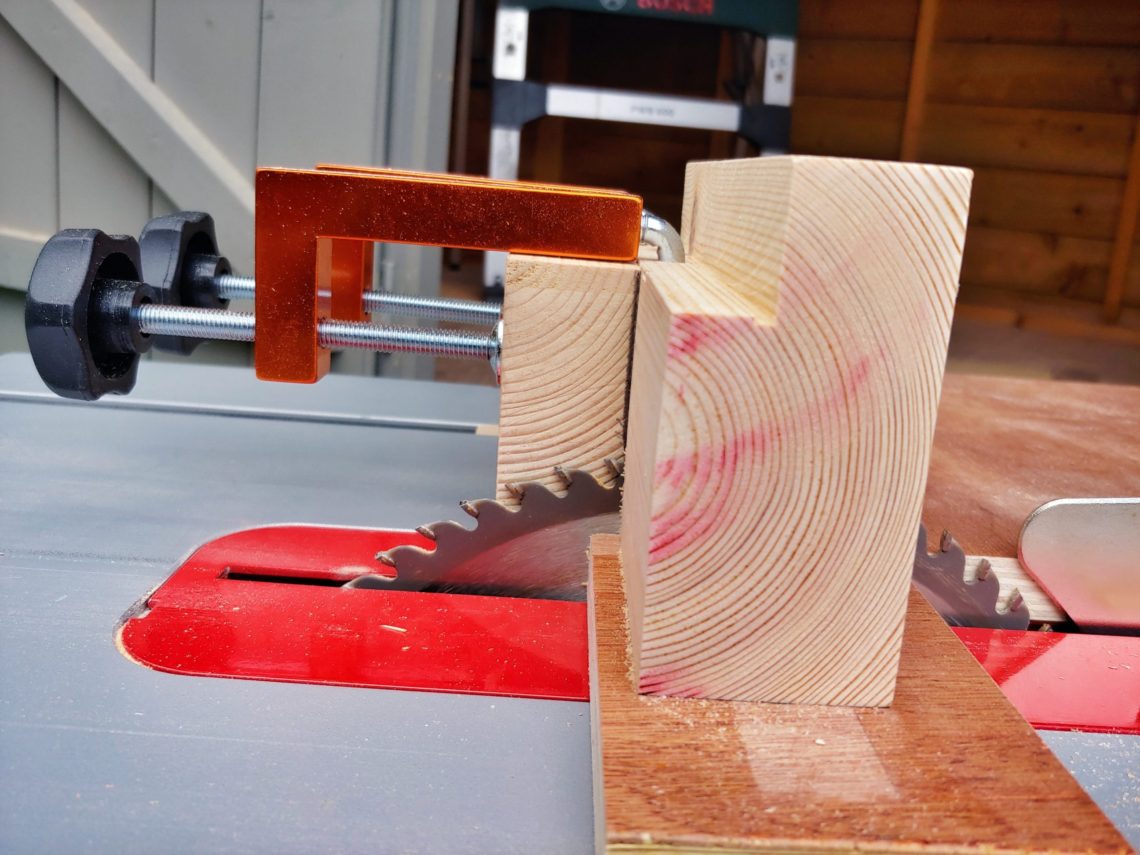

Next, I drilled 2 holes for the fence clamps on my drill press. Using my metal chop saw I cut an unused and unwanted steel spanner to the size. I eased its edges after the cut was done, and cut a recess in the jig for it. The width of the blade was exactly the same as the thickness of that spanner, which was 2.8 mm (7/64 inches). I was trying to install the pin with hot glue, but that didn’t work. Eventually, I used PVA glue and that worked like magic.

Next, I attached the plywood foot, without regard for the proper (2.8 mm) distance or gap, I left it intentionally smaller, made a cut and removed the excess material. But the jig itself was clamped to the fence at the right position as I used a metal spanner off-cut as a spacer to move the pin away from the blade.

I tested the jig straight away and it seemed to be working well. Finger joints were nice and tight. All the materials intended to use with this jig will be bigger/thicker than the size of the metal pin. It’s not one for all and all for one.

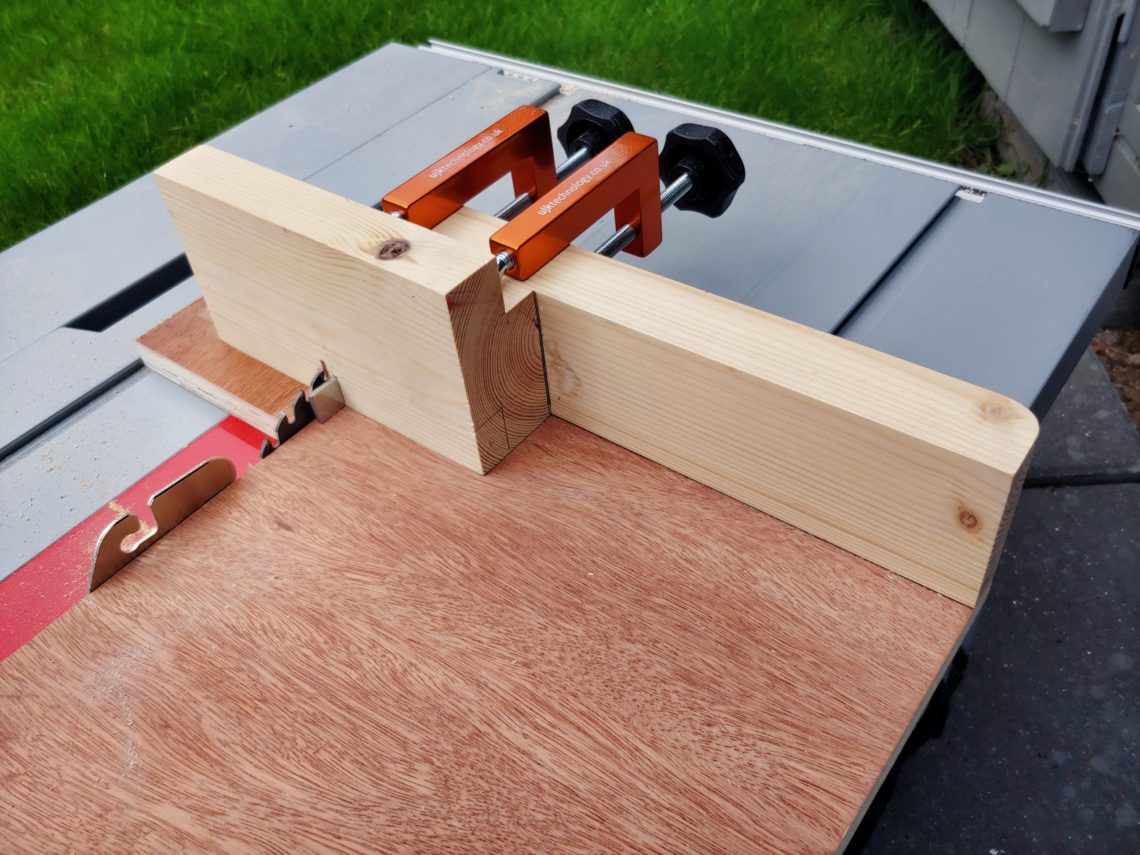

The jig looked good while attached to the sledge. When unattached – a little funny or skinny on its own.

And without clamps, it looked hilarious, it was just 2 wooden pieces and 1 metal bar. The holes in the plywood foot were even drilled a couple of years ago, and countersunk for another project. That’s why there are 3 of them and not 2. Re-using and upcycling everything.

I marked some lines with a pencil, as a reference for future use, it should be easier to set up the jig when the time comes. For me it’s important that it’s working well, it’s easy to store and it comes from upcycled and scrap materials. Very happy with this project and the way it turned out. It is a must-have jig for me, I’ve made a couple of attempts to make boxes, like my box joint jig which was only used for one project, and a drawer router bit that didn’t work for me and maybe a few more examples… This one should be universal for most of my future projects, if not, I’ll make another one!

3 Comments

Pingback:

Pingback:

Pingback: