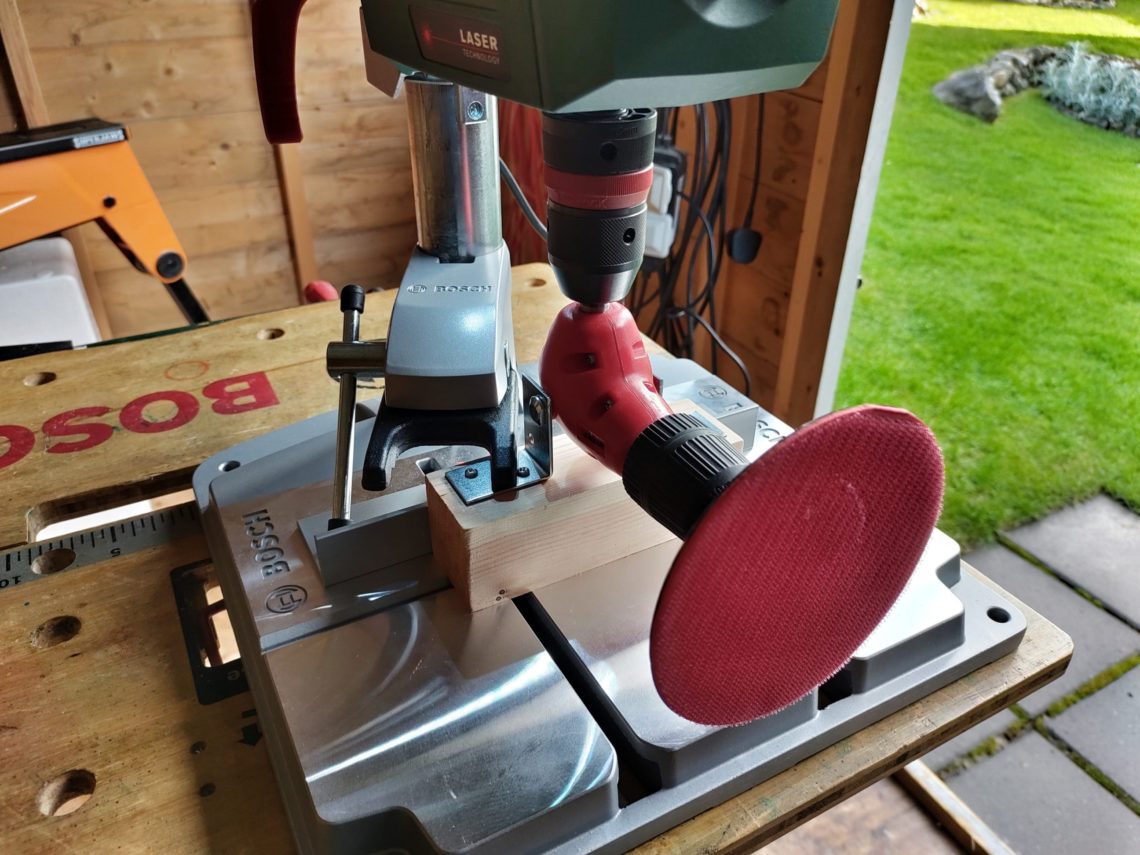

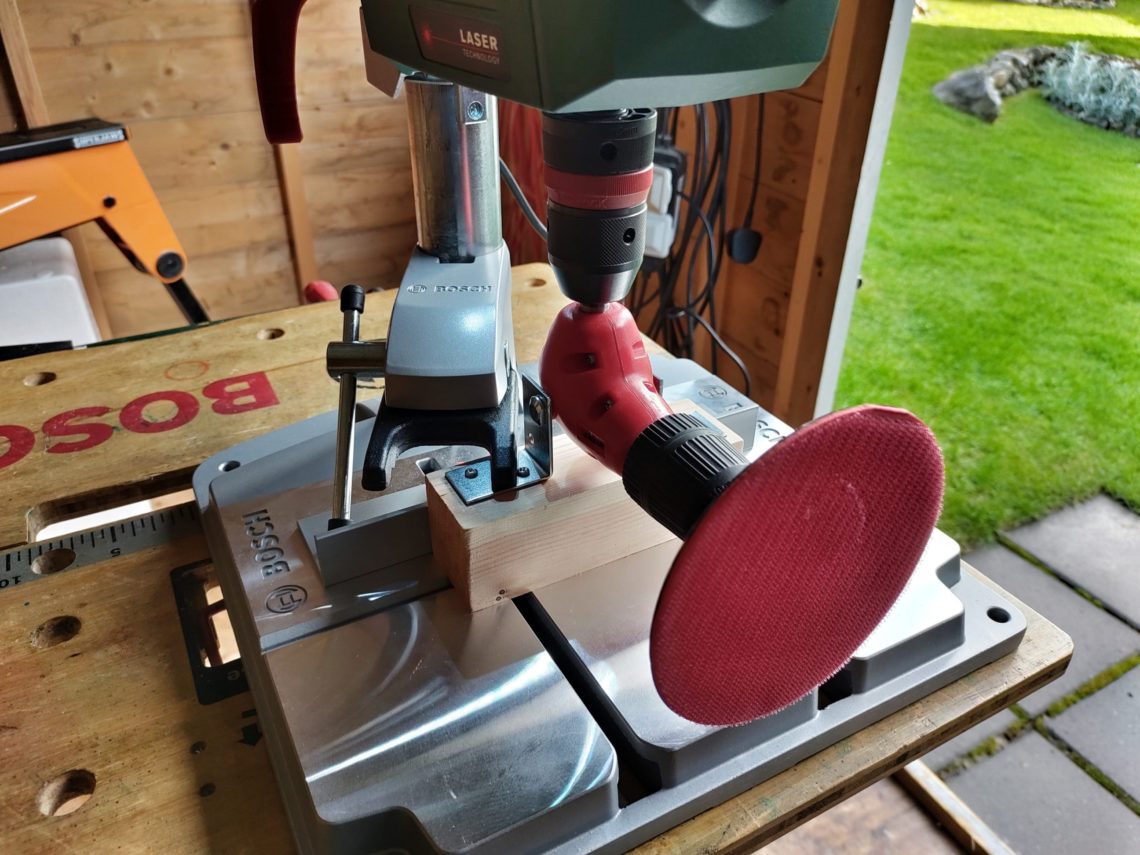

Vertical-to-horizontal drill press jig

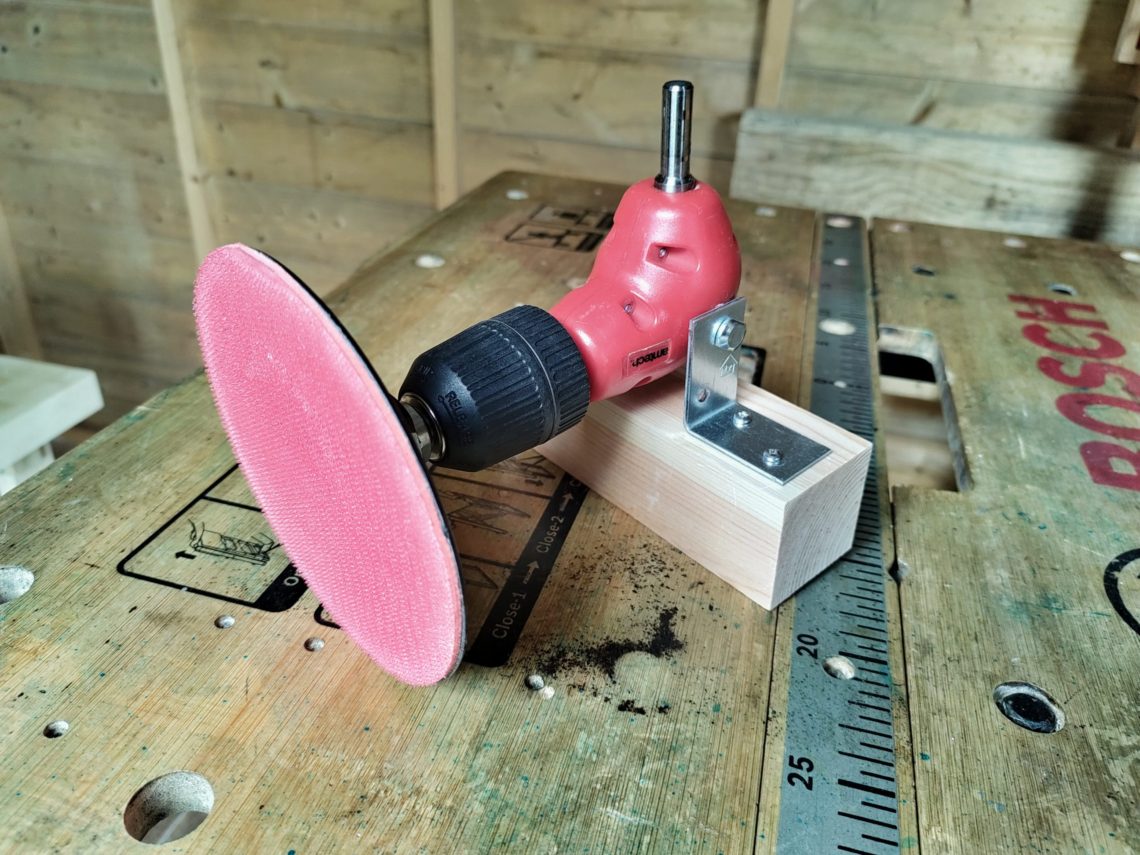

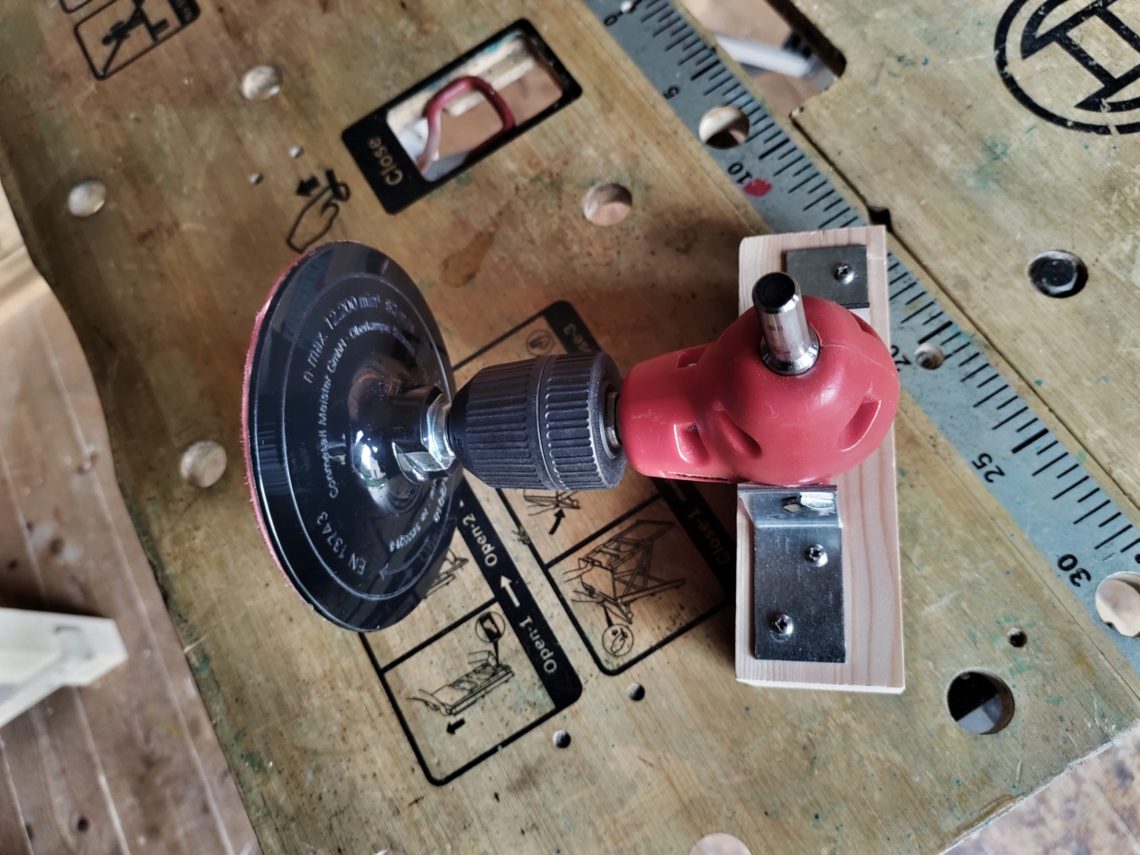

This jig comes in handy when I have to process cut bottles. I stick sanding discs to the velcro pad and polish the glass. For any other tasks i.e. wood and metal, I use my disc/belt sander, but for glass, I like to sand through the grits, from coarse to very fine. That wouldn’t be easy with a bench sander as it uses self-adhesive discs and offers no control over the sanding speed. Glass is different and it likes to be sanded slowly – excessive heat can crack the glass and melt the velcro backing pad. That’s why I built this jig. It’s very cheap and simple to make. Apart from the right-angle adapter, I used 2 short bolts, 2 angle brackets (corner braces), a couple of wood screws and a wooden block.

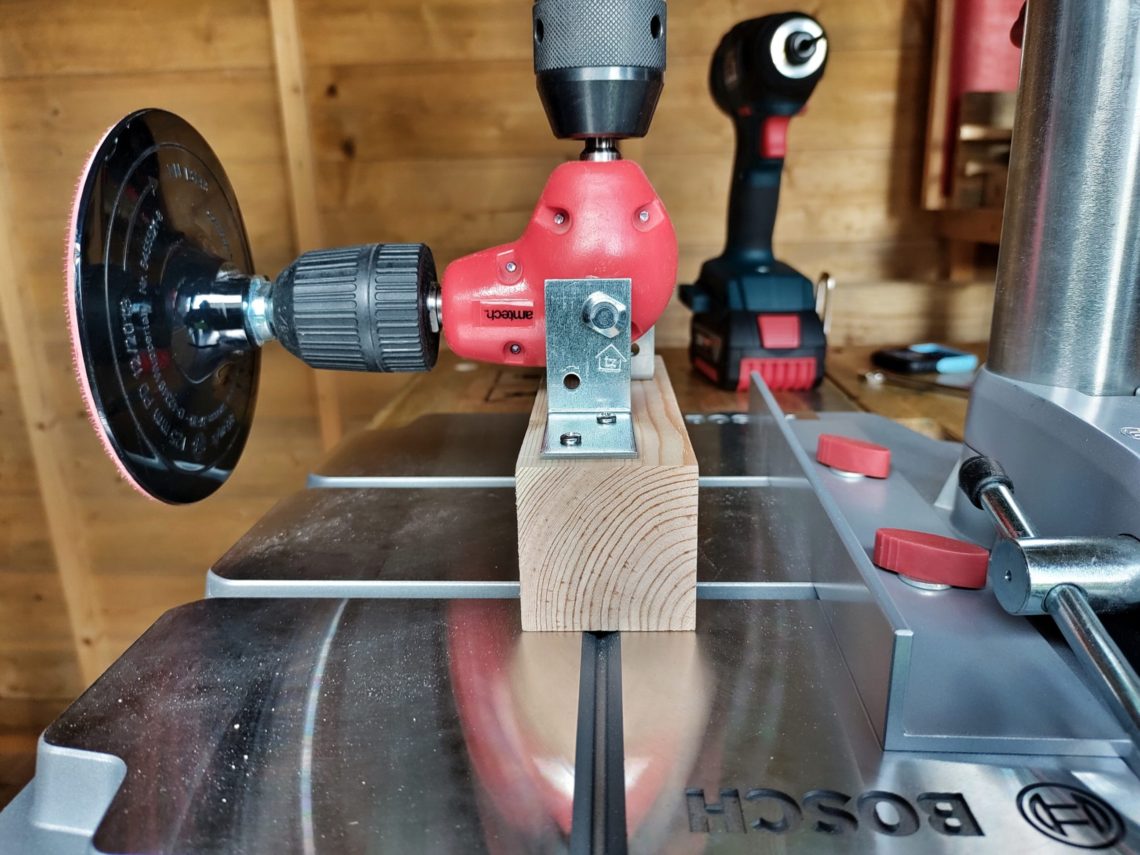

First I had to resize holes in the corner brackets. I used a step drill bit for that task. Next, I fixed the brackets to the adapter and to the wooden block. Pan-head screws seemed to be perfect for that project, no pre-drilling was necessary, those screws were quite small and needed a PZ1 bit to drive them into the block.

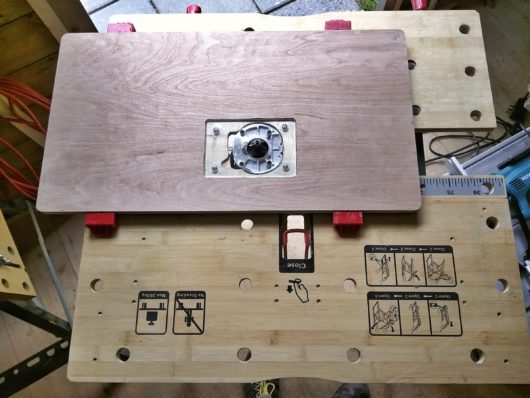

There was a special sequence or a procedure that I made up for setting up the jig: first, it had to go into the chuck, then it was lowered down until it sat firmly on the base plate. Next, I slid the fence (parallel guide) towards the jig and then I clamped everything with an onboard quick-release clamp.

And so it is – a simple jig that is necessary for glass processing. Perfect working height, perfect angle and adjustable speed thanks to the drill press. That’s all I need when I sand the glass.

One Comment

Pingback: