Bottleneck vessel

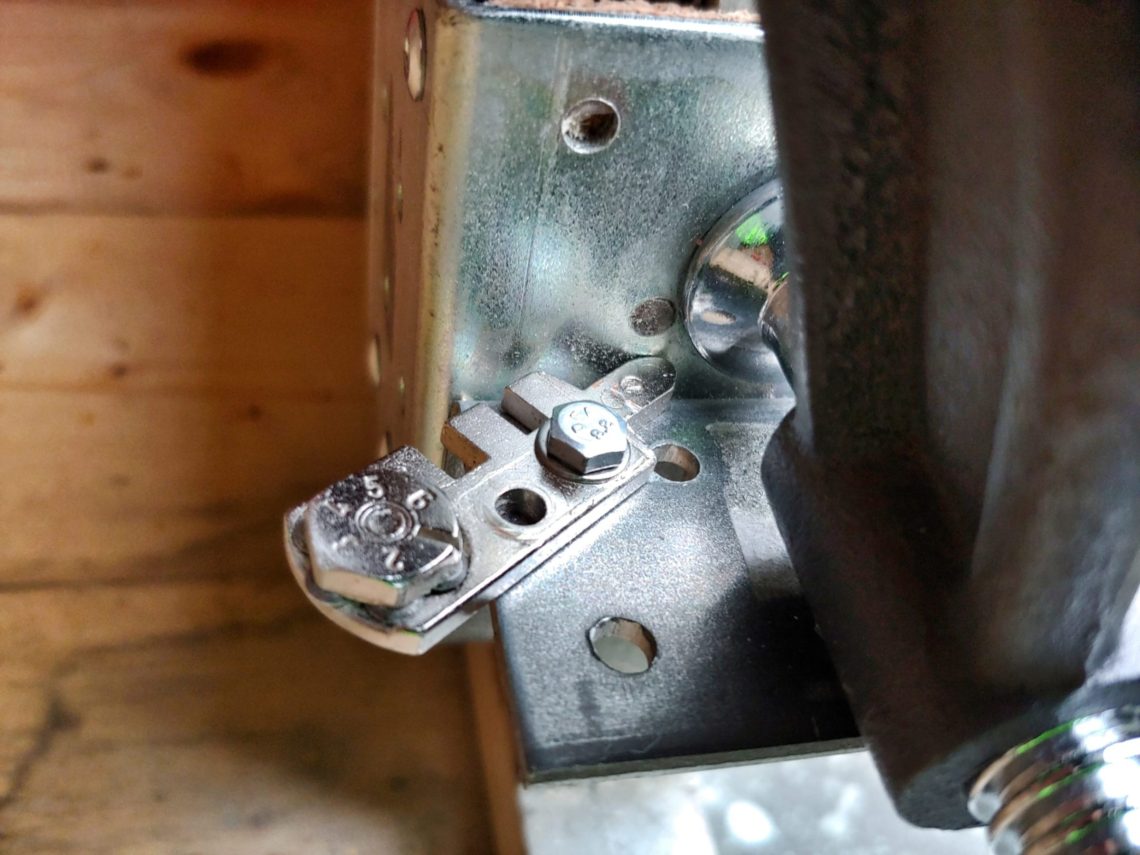

In order to cut the bottle I had to set the glass cutter at an angle. That gave me good access to the bottleneck. This jig has many limitations due to the way it’s built and fixed to the wall.

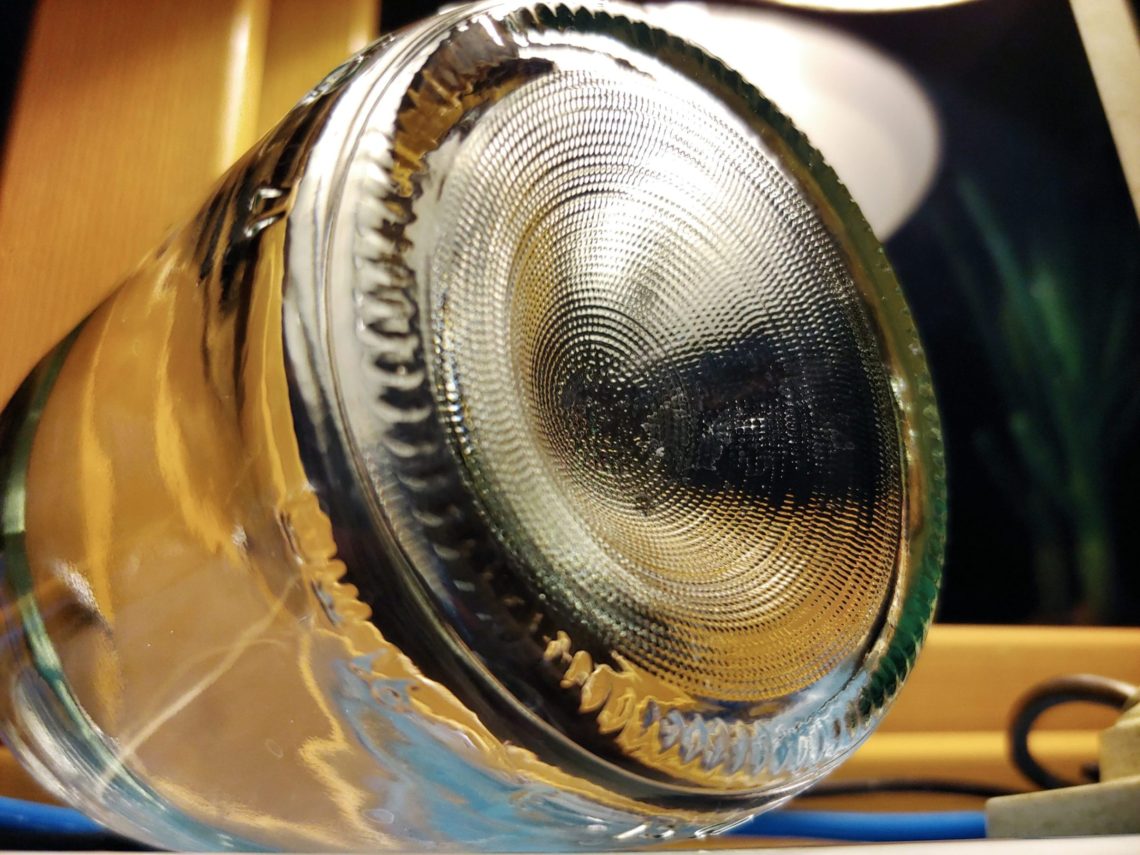

Cutting was easy and fast, the bottle cracked as planned and the labels came off easily. Smoothing sharp edges was done in 2 steps, as always – outside first, inside next. This is 40 grit:

I finished sanding with 3000 grit for the outside and started sanding the inside. I used 3 grits: 240, 400 and 600. Polishing was next, however, it was very cold outside so I had to use my heat gun during the polishing process. I heated up both the felt disc and the compound.

Quick cleaning and it was ready to use.

One Comment

Pingback: