-

Small rustic planter

Made of pressure-treated wood, cut with a hand saw and put together with nails and butt joints. Simple and quick project, but quite enjoyable as it involved woodworking and gardening. It’s just this time of the year, perfect for combining these two. There was a need for another planter and there was leftover wood, so I measured the board, marked the cut lines and cut the pieces I needed. A sharp hand saw did the job in no time. I used the simplest approach to join the boards together, and that was nails and butt joints. To give some structural…

-

Post on runners, a stand

Simple construction and the look that matches my other projects in the room, i.e. my pedestal table and the cascade shelf. I used scraps to build this platform, some of them were even pre-finished with lacquer. I didn’t want to remove that finish from them but also wanted to treat the charred wood with oil. The top coat on both of them had to be glossy lacquer. Luckily, a combination of oil and lacquer is completely fine, as long as the oil has fully dried first. I started the build by removing the twist from the post, I clamped it…

-

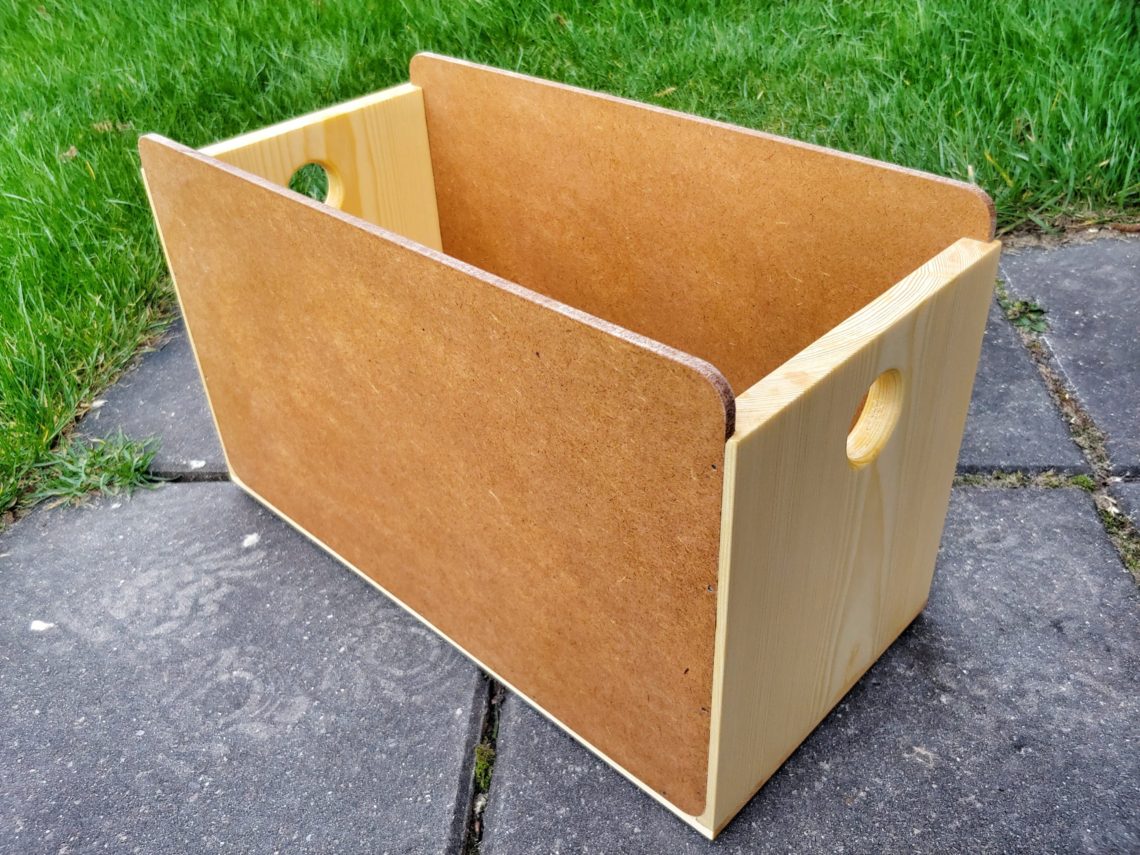

Handy-dandy box

The box is made from a 1 x 9 pine board and a 6 mm MDF. Large and sturdy, good for storing anything and everything. I wanted to try out 2 router bits to cut self-locking corners, I had used them in the past with rather bad results and this time I just double made sure that they were not going to work for me. Before throwing them away I had to give them a last chance, or at least one of them as the other one works using the same principle. I started by cutting the 1 x 9…

-

Towel shelf

Designed for use with hand towels, each rolled up and suspended onto 2 dowels. A light-duty construction made with good quality materials and simple enough to not overwhelm the beauty of fresh towels. It’s built to stay in the background, not showing its structure and playing the supporting and not the leading role. I started by ripping the thickest one exactly in half and roughly cleaned the surface with a block plane. Then I attached a fence extension which worked as a stop block and cut 5 rails that were further processed in the next step. I wanted a partial…

-

Simple incense stick holder

This may be the smallest, the lightest and the most delicate project I’ve ever built. Scrap wood pieces I used, were very thin and tiny. However, they were straight, flat and relatively smooth, which made the project easier. Even still, I had a chance to practise my skills and learn something new. It turned out very good, but the feature I like the most is the large space for ashes. I cut pieces to size using an oscillating tool. Sanding was also done with the same tool. That was the last time I used it, it was sold the next…

-

Whale-shaped cooking spoon rest

It didn’t start as a project. I was just practising my power carving skills, I also wanted to try out my new carving disc. I have a couple more of them, different shapes for different uses. I picked up that old tabletop, it was dumped in the corner and covered with dust. I pulled it out and clamped it to my workbench. I discovered that this particular carving disc couldn’t be used with a guard, it simply didn’t fit. Even though there was no physical barrier between me and the disc, it was reasonably safe as the carving itself didn’t…

-

Cascade shelf

This project is entirely made from scrap material – timber off-cuts I acquired last year and a wooden dowel. The off-cuts had different lengths, from 60 to 90 cm (2 – 3 feet) and I had to get shorter pieces out of them, anything from 10 to 50 cm (4 – 20 inches). I tried not to cut them into 2 identical lengths, also not to produce too short pieces. All that came down to the planning which took much longer than cutting itself. Anyways, eventually I had it done and the next step was to recreate the rounded over…

-

MDF box

I’ve always wanted to give those corners a shot and see how they perform. I still had some scrap material to build them from and also I had a 6 mm MDF board (1/4″) that was perfect for the walls and the bottom. The corners looked a little complex to build, but when all the cuts were done in the right order, there was really nothing complicated about them. Easy and safe to cut, using just a couple of basic tools like a table saw and a router. Here’s how it started. First I rip-cut the timber to the desired…

-

Circus flautist

It’s like addiction, making these heads of The Wall Heads series. There was no plan for this one, just a blurred vision that changed a few times during the build. It’s got its name because it looks like a flute and it uses the colours of a clown’s make-up. I started with drilling holes, the eyes were first, then the finger holes and lastly the mounting holes at the back. Each group of holes was drilled with a different bit – 30, 15 and 25 mm. Once I finished with the drill I pulled out my circular saw and cut…

-

Sycamore coasters

That sycamore (maple) tree was cut in late 2018. I saved a couple of logs, split in half with an axe on a site. I’ve never considered milling them into boards just because they’re so irregular, and I’d need a jig, or a fixture, to cut them with a bandsaw. They seemed to be perfect for small projects using block-shaped wood, single-part projects, art etc. Just like coasters. Yes, another set of coasters, with no holes in the bottom for a change (see “3 button coasters”). They should be great for drinks, hot and cold, but also for large candles…