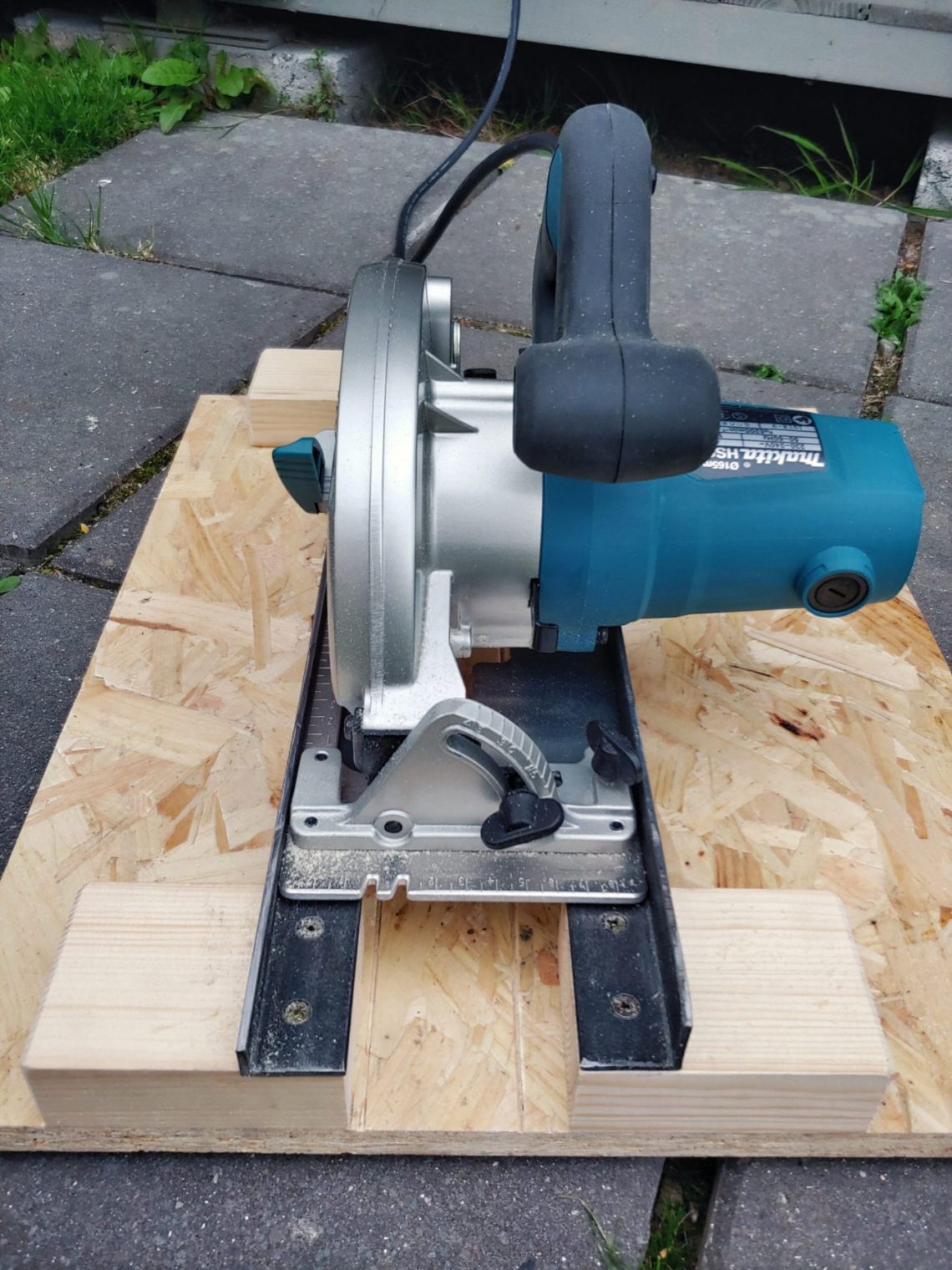

Circular saw jig

It’s made of OSB, steel and spruce timber. Simple and stiff construction, ideal for cutting long pieces of timber such as skirting boards. Cutting at 2 angles: 45 and 90º made easy.

(The post Improved circular saw jig can be found here)

The first thing to do was to trim the board to length. It was an easy job for my recently bought circular saw. 4 supporting pieces I cut on my table saw as they were too small for any other tool.

The steel corner I bought had to be cut in half, but that was the easy part. Each of the halves had to be cut lengthwise using an angle grinder. I used different approaches for each half because they had different heights but in general, the disc sequence was the same: cutting, grinding and sanding.

With my router, I created a dust channel in the block pieces. Next, I drilled some holes in the back of the board.

Once that was done I moved to the next step which was drilling and countersinking holes in steel. Once screwed together at a 90º angle and perfectly parallel to each other, the rails were filed, sanded and waxed.

Next, I lowered the blade just to touch the OSB and cut grooves at both 45 and 90º angles. I used some scrap material to test the jig.

It seems to be working fine, its capacity is just enough for skirting boards. Mission accomplished!

4 Comments

Pingback:

Pingback:

Pingback:

Pingback: