Garden hose stand

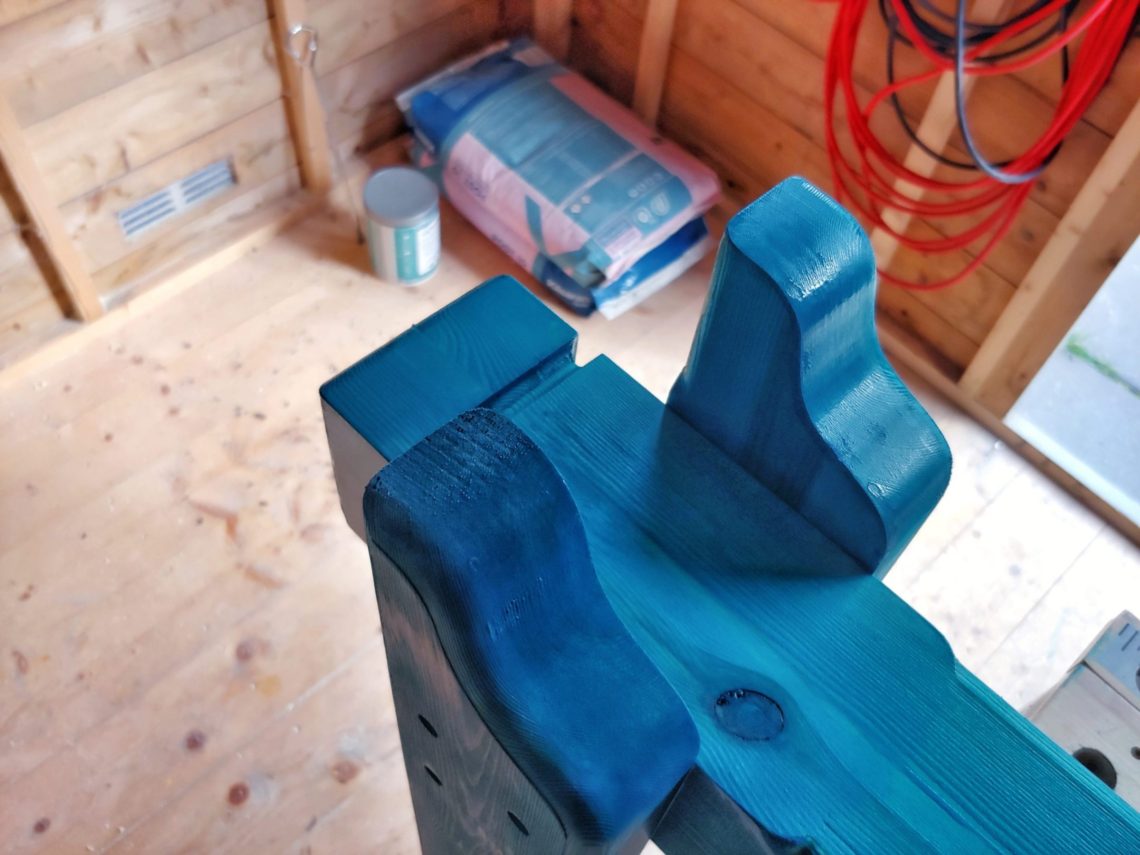

It’s usually an arch that supports the hose, but in my build, I’m using 2 rounded bars. I am hoping that there won’t be any kinks and dents in the hose and the whole construction will last for years.

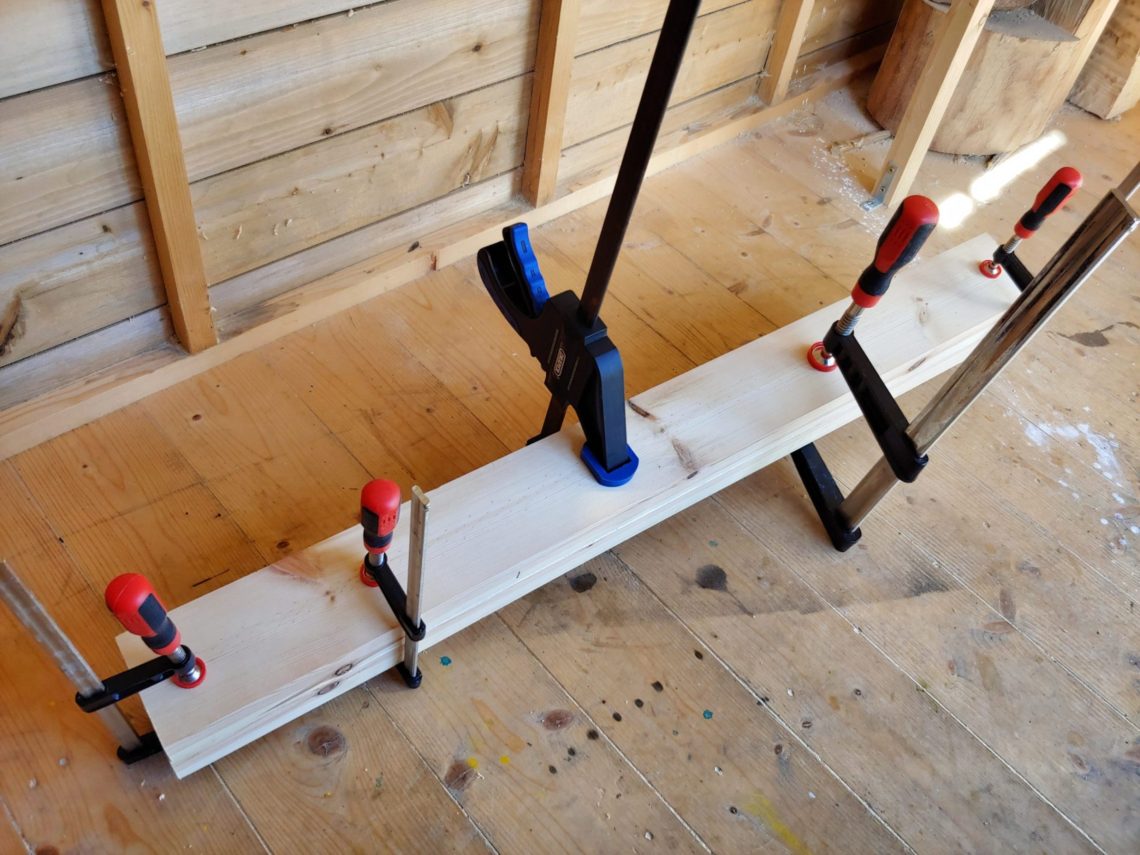

Once I had all the timber cut to size I used my hole saw to remove some material from the horizontal pieces. As the material was too thick I had to proceed with my coping saw. To clean the cut I used the hole saw again. I then roughly removed the corners with 2 tools – a coping saw and a rasp. It was then ready for sanding. The last thing I did that day was glueing up the post.

Sanding with 120 and 240 grit was the only option at that time, those were the only sanding belts I had on hand. Sanding produced a lot of dust!

Next, I took out my orbit sander and sanded all the pieces up to 240 grit.

Free-hand routing with and without the fence was next.

I then installed my router table top on the workbench and finished the horizontal pieces.

The pieces were joined with 5 x 80 mm screws.

I used an exterior stain to finish the stand. UV and water-resistant, 2 coats. While the stain was drying I went to the shop and bought some ready-to-go concrete mix.

Ground and concrete works were next. The hole I dug wasn’t very deep but it should be enough. I used 4 bags (20 kg each) of concrete to fill up the hole.

After 1 week I drilled holes in the concrete base. Using a straw I blew out any remaining dust. I also installed the metal braces to the post and then I screwed it to the concrete manually.

I put some big stones on the outside and smaller ones on the inside, hung the hose and washed everything with water. I used the shorter arms to make smaller loops. It was easy to wash my hands after work as the nozzle was nicely hanging down and also use the post to place my can of cider.

There are no kinks in the hose, it seems to be working well. I hope it will serve well.

2 Comments

Pingback:

Pingback: